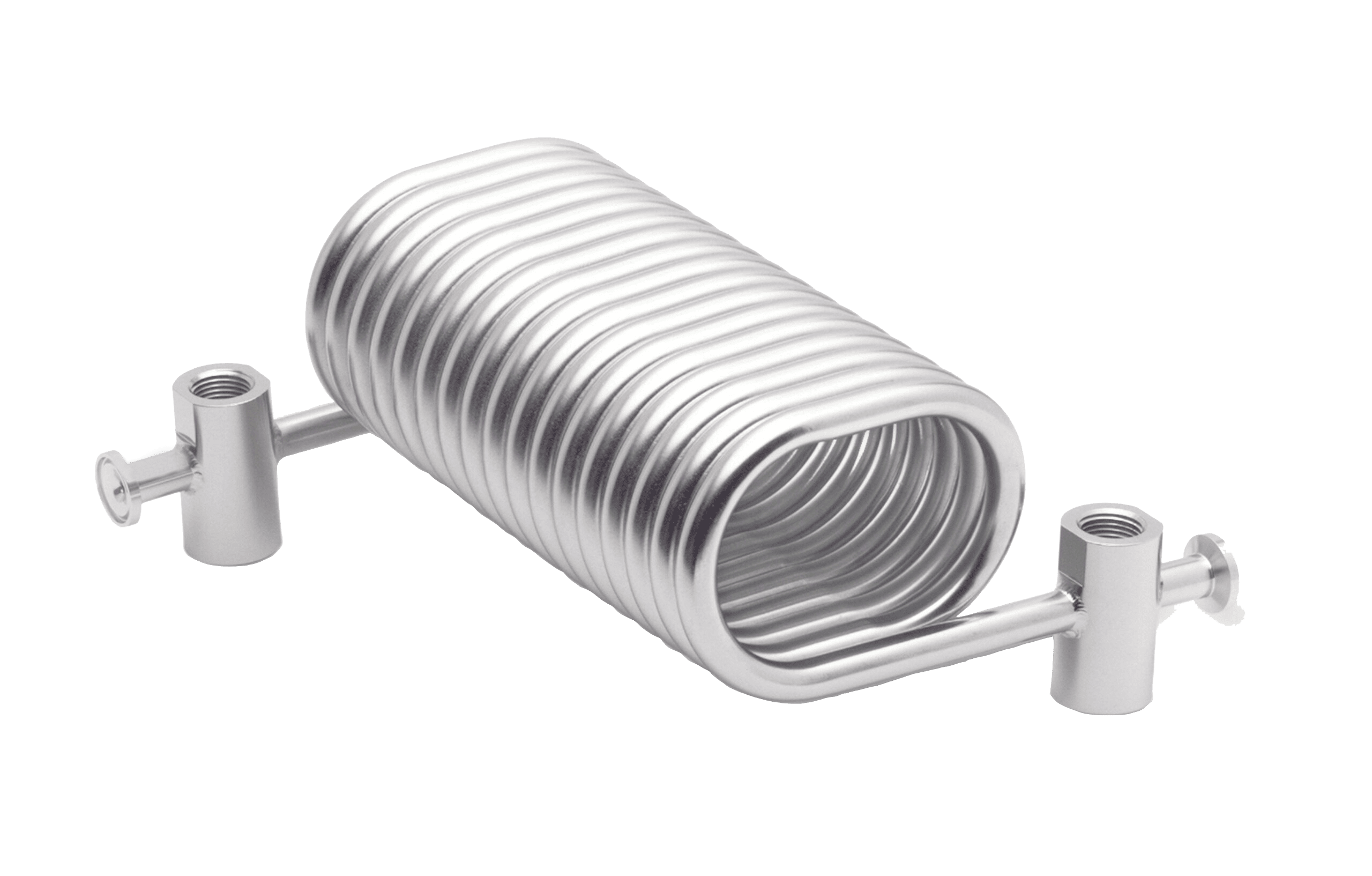

Exergy sanitary tube-in-tube heat exchangers feature a precision-engineered dual-tube configuration, with an inner and outer tube coiled together to form an exceptionally compact, high-performance thermal solution. This robust design minimizes thermal fatigue, maximizes heat-transfer efficiency, and reduces system footprint—making it ideal for high-temperature, high-pressure, and low-flow pharmaceutical processes.

Tube-in-Tube Working Fluid

Handles multi-phase fluids and slurries with smooth flow paths that reduce fouling and protect product integrity.

Accommodates rapid temperature changes while maintaining mechanical stability and consistent performance.

Delivers precise heat transfer under extreme temperatures and pressures where low flow rates demand tight control.