Process Heat Exchangers

Compact, Reliable, and Engineered for Precision

Exergy’s low-flow process heat exchangers are engineered to deliver maximum thermal efficiency and reliability in demanding applications. Designed with a compact footprint and built for durability, these exchangers solve critical challenges like space constraints, precise temperature control, and harsh operating conditions.

Whether you’re managing cryogenic cooling, batch process heating, or regenerative heat transfer, Exergy’s Shell and Tube and Tube in Tube heat exchangers offer unparalleled performance, tailored to your specific needs.

Exergy’s heat exchangers combine three essential features for industrial processes:

- Compact Design: Save valuable floor space with exchangers that pack a large heat transfer area into a small volume.

- Engineered Precision: Exergy’s Compact Shell and Tube Heat Exchangers are designed to deliver consistent thermal performance in demanding process applications. Their reduced shell-side flow demand supports rapid steady-state status on PID control valves, enabling precise process temperature management within ±0.1°F. When integrated with the appropriate control systems, Exergy’s design ensures accurate temperature regulation without impacting the target temperature.

- Custom Solutions: Exergy engineers heat exchangers to fit your exact application, from material selection to configuration.

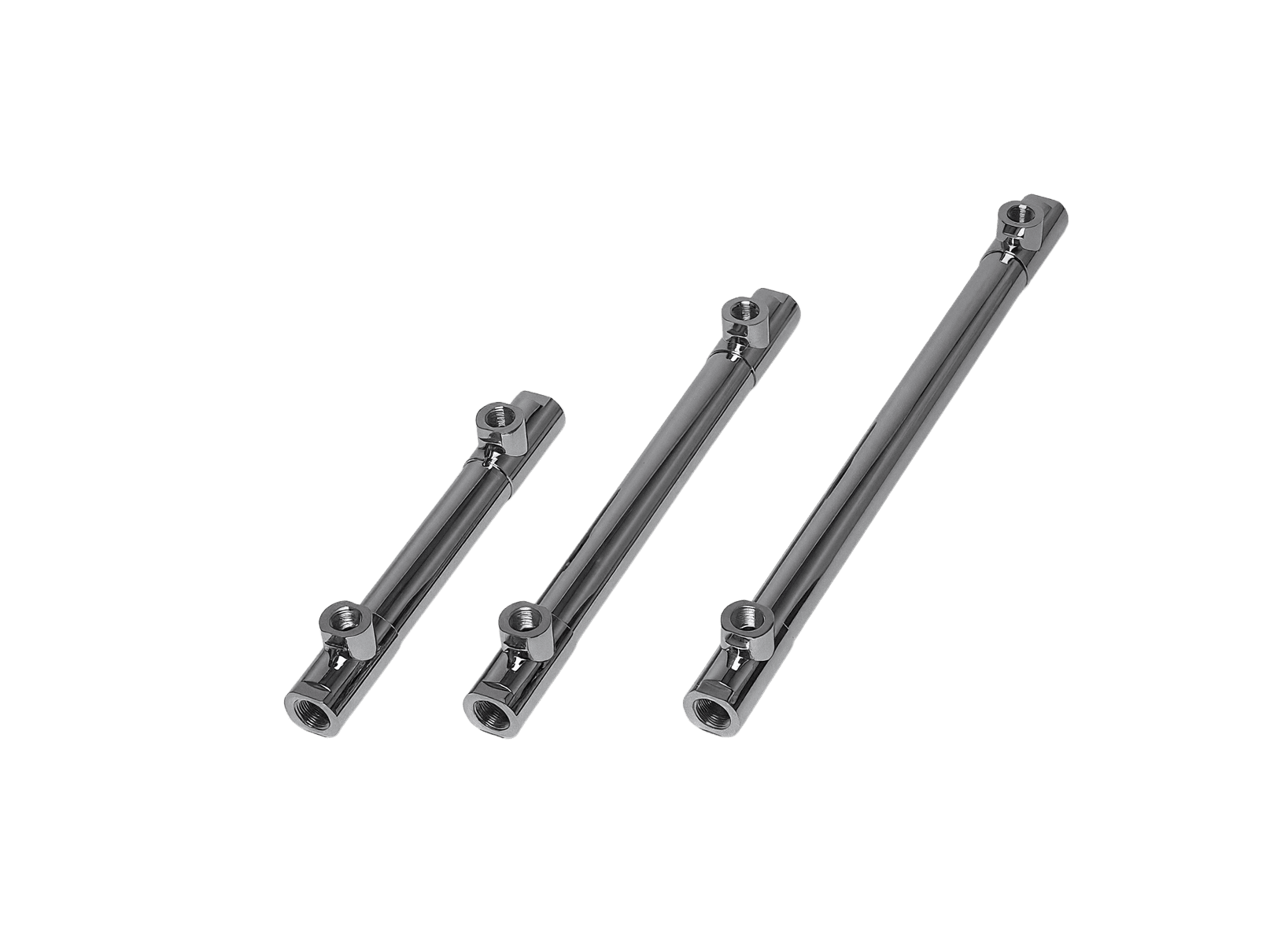

Exergy Low-Flow Process Shell and Tube Heat Exchangers

Precise Temperature Control in a Compact Footprint

Exergy’s Shell and Tube heat exchangers stand out for their ability to achieve temperature control within ±0.1°F, making them the most precise option for applications requiring exact thermal management.