Products

Sanitary Heat Exchangers

In sanitary processing environments, especially within the pharmaceutical, biotech, and food industries, cleanliness and contamination prevention are non-negotiable. That’s why a properly designed sanitary shell and tube heat exchanger is essential.

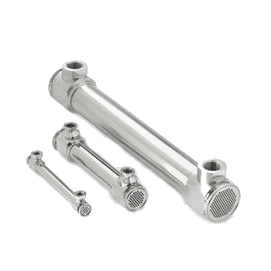

Sanitary Shell and Tube

Heat Exchangers

In industries where hygiene and process integrity are paramount—like pharmaceuticals, biotech, and personal care—the sanitary tube-in-tube heat exchanger is a trusted solution for heat transfer in low-flow, high-pressure applications.

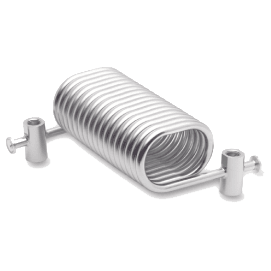

Sanitary Tube-in-Tube

Heat Exchangers

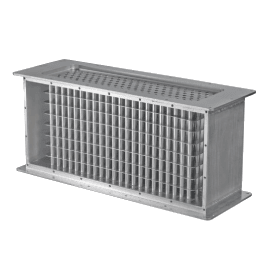

Process Heat Exchangers

Low-flow process heat exchangers are engineered to deliver maximum thermal efficiency and reliability in demanding applications. Designed with a compact footprint and built for durability, these exchangers solve critical challenges like space constraints, precise temperature control, and harsh operating conditions.

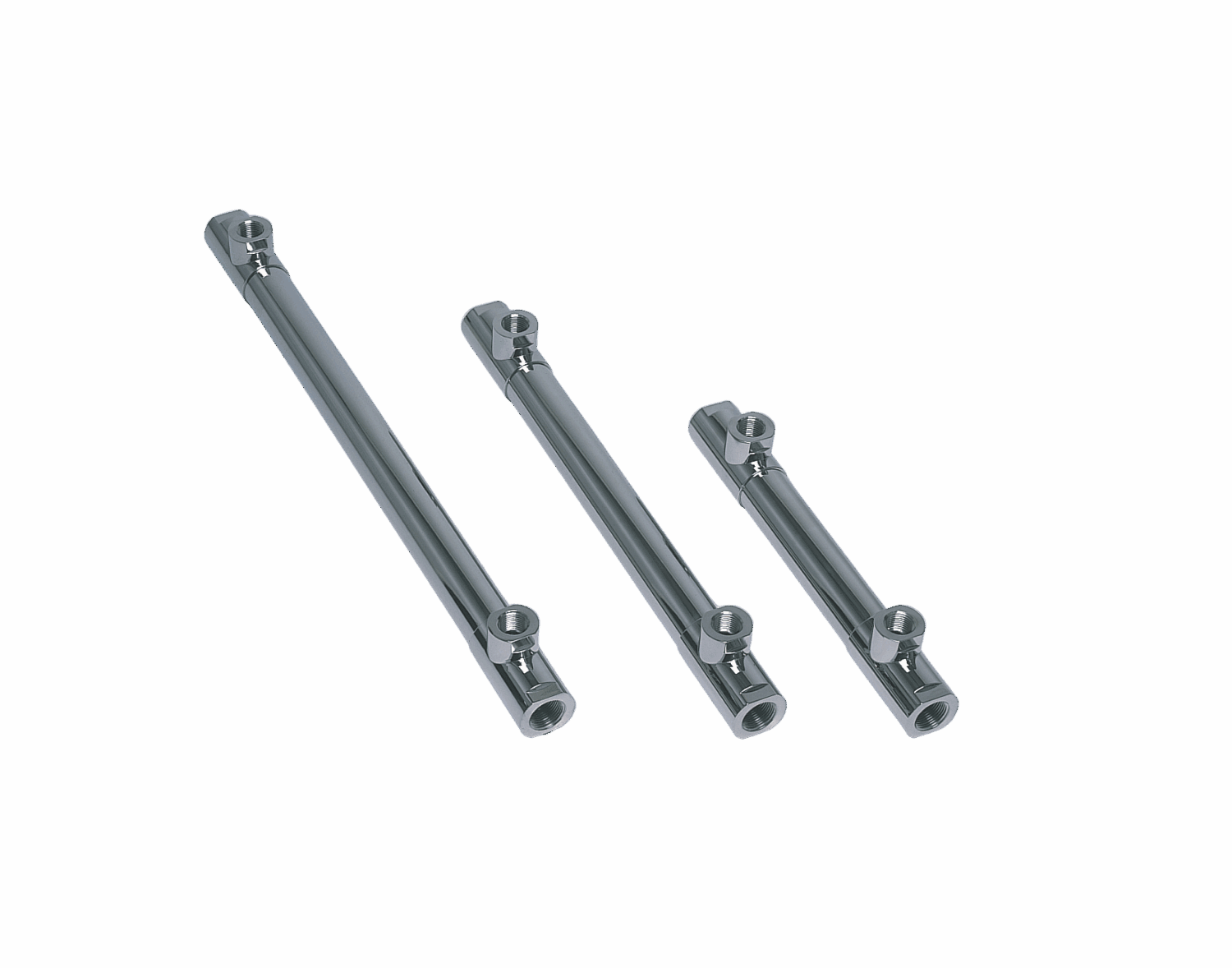

Shell & Tube

Heat Exchangers

Low flow tube-in-tube heat exchangers are engineered for high-pressure, low–flow processes. Exergy’s tube-in-tube heat exchangers deliver the durability and thermal efficiency needed for demanding applications. Built to perform under pressure, they provide long-lasting, reliable solutions where space and performance matter most.

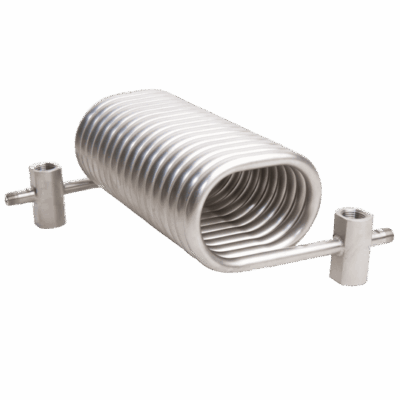

Tube-in-Tube

Heat Exchangers

PureX Dispensing Systems

PUREX Point-of-Use Dispensing Systems deliver instant, temperature-controlled WFI or PW with the reliability and hygiene demanded by the pharmaceutical industry. During idle periods, a continuous flow of hot water from the main loop ensures ongoing sanitization. Built around Exergy’s compact, high-performance heat exchangers, our standard models are engineered to handle even the most demanding operating conditions.

Point-of-Use WFI/PW

Dispensing System

PUREX Clean Steam Sample Cooler

plays a vital role in pharmaceutical and biotech production—and verifying its purity is non-negotiable. The steam sample cooler is engineered for portable, accurate, and convenient steam sampling anywhere in your facility, ensuring confidence in compliance and quality.

Steam Sample Cooler

Sampling System

Custom Heat Transfer Products

Exergy delivers maximum performance in the most compact, cost-effective designs. If a standard model doesn’t fit your application, our engineering team applies decades of expertise and proprietary design methods to create a custom solution tailored to your needs.

From minor modifications to fully unique designs—produced in any quantity—Exergy has the capability to deliver. Connect with an Applications Engineer today to discuss your requirements.